STICHWEH jigs - you can rely on them: To remove undesirable components such as alkali-reactive or organic substances from gravel, you can rely on STICHWEH jigs are the right partner at your side. The classification process using jigs utilises physical principles, in particular stratification according to differences in density, and thus enables precise separation.

Important aspects of the method:

Loosening up the material:

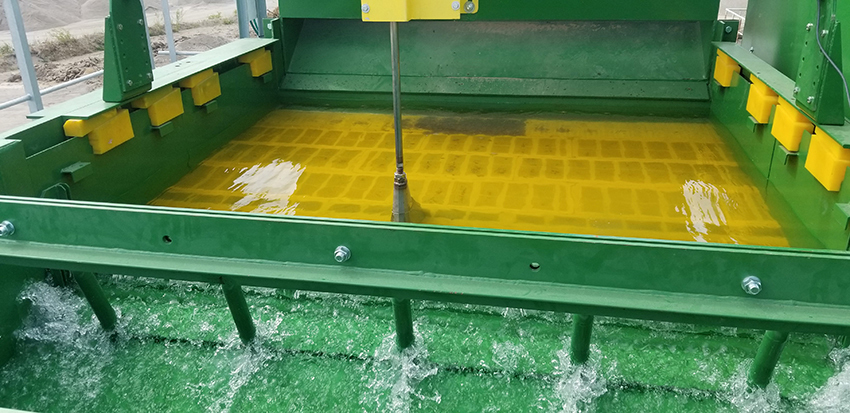

Pulsating water flows through the material, creating uniform layering according to density differences.

Fine adjustment of the jigs:

Thanks to air pulsation, the machines can be set to recognise and use even slight differences between gravel and interfering components.

Flexible control of water pulsation:

Parameters such as frequency, amplitude and control times can be adjusted during operation to make sorting even more precise.

Automated discharge:

The cleaned heavy material is automatically separated, classified and dewatered after stratification.

Coarse-grained material is discharged automatically via a rotary feeder. Further processing or dewatering takes place via a dewatering screen or a classifying screen.

For fine material (sand) automatic discharge takes place via a bottom gate. Further processing or dewatering takes place via a dewatering screen or bucket wheel.

Efficient further processing:

The cleaned gravel is fed to the raw material store via conveyor belts.

More info: STICHWEH jigs

Example in use: STICHWEH jigs in use