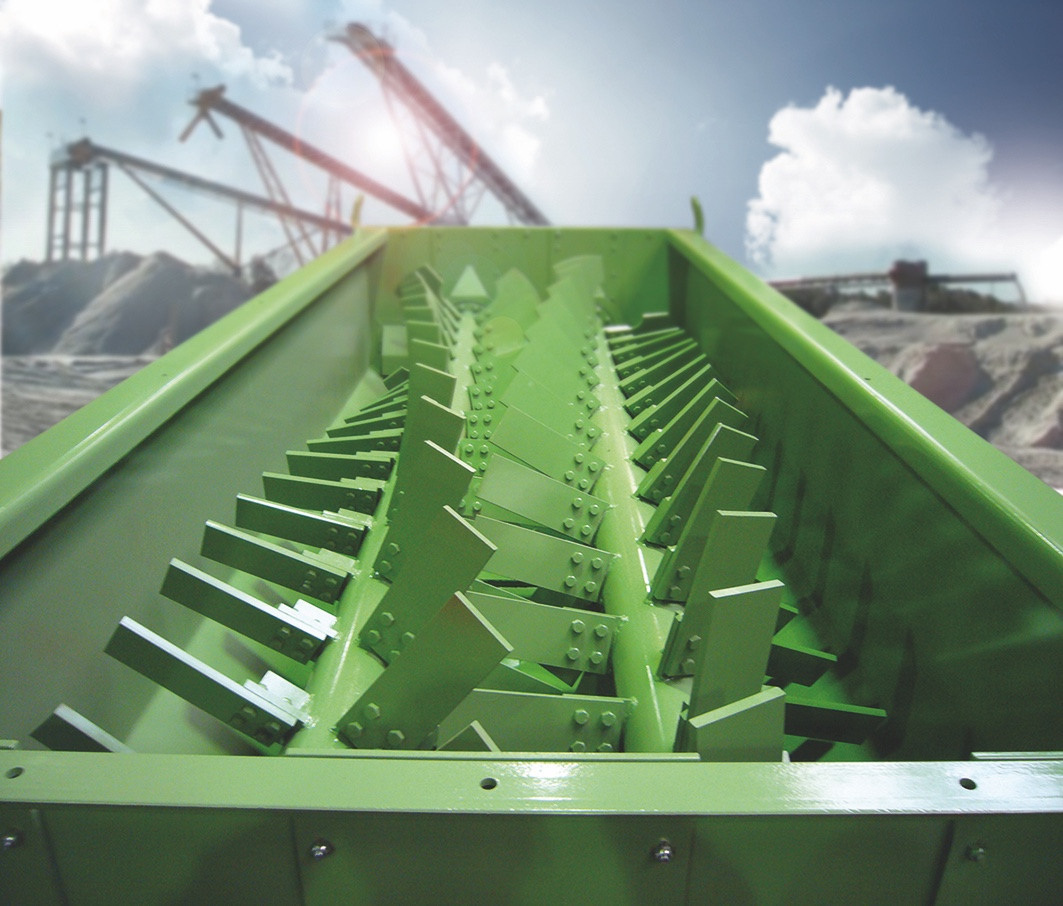

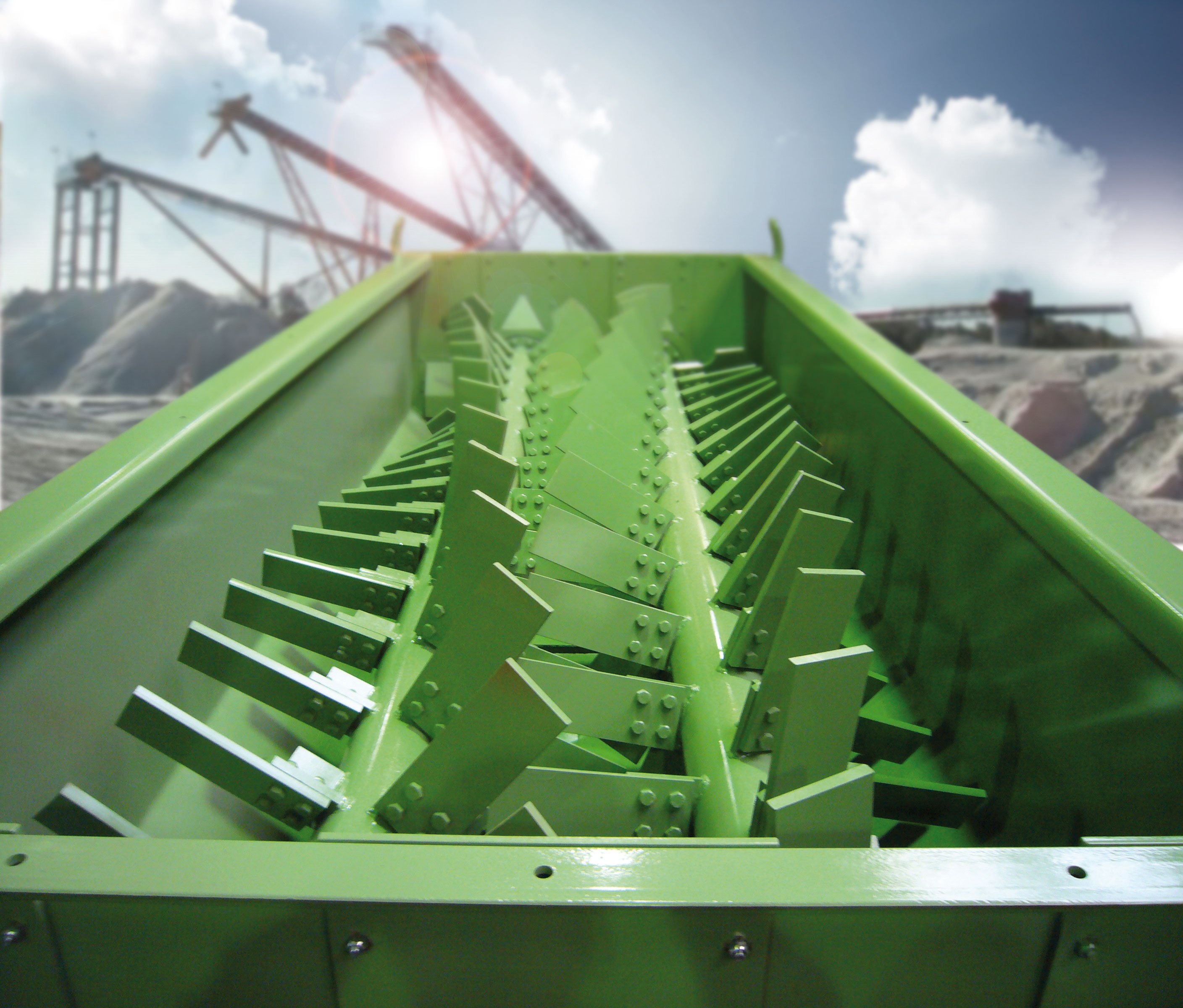

log washer

Clean raw material

The professional log washers programme

The preparation of raw materials often results in heavily soiled raw material.

To effectively clean heavily soiled gravel, crushed stone or sand, STICHWEH offers log washers - depending on the task - as single or double-shaft log washers.

The cleaner

Log washers are used to wash heavily soiled gravel, crushed stone or sand and to remove wood and other impurities.

The STICHWEH professional programme for log washers is available on request with load-dependent frequency control, with a sturdy trough made of folded sheet steel and an indestructible drive consisting of a gear drive in an oil and dust-tight gearbox

Functional high quality

The contaminated material is fed into the log washer at the lower trough end and transported to the upper trough outlets by the counter-rotating sword shafts.

Contaminants are pulverised and dissolved by the corresponding friction. Dirty water and light weight parts flow off in the lower area of the trough.

This effect can be further enhanced by the upstream devices, so that wood and coal can also be partially separated out.

Log washers programme

STICHWEH log washers prove their worth even under the most difficult operating conditions and impress with their high quality: The abrasion resistend paddles are made of highly wear-resistant steel (Brinell hardness 500 - 600) or special materials. The special arrangement of the abrasion resistend paddles ensures smooth and quiet running.

Examples of different log washers:

Log washers with a conveying capacity of 50 - 300 t/h

Log washers in different trough weights and special designs

Log washers with a trough lenght of up to 8000 mm

Log washers with special air flow device

Media / Downloads

- Product documentation