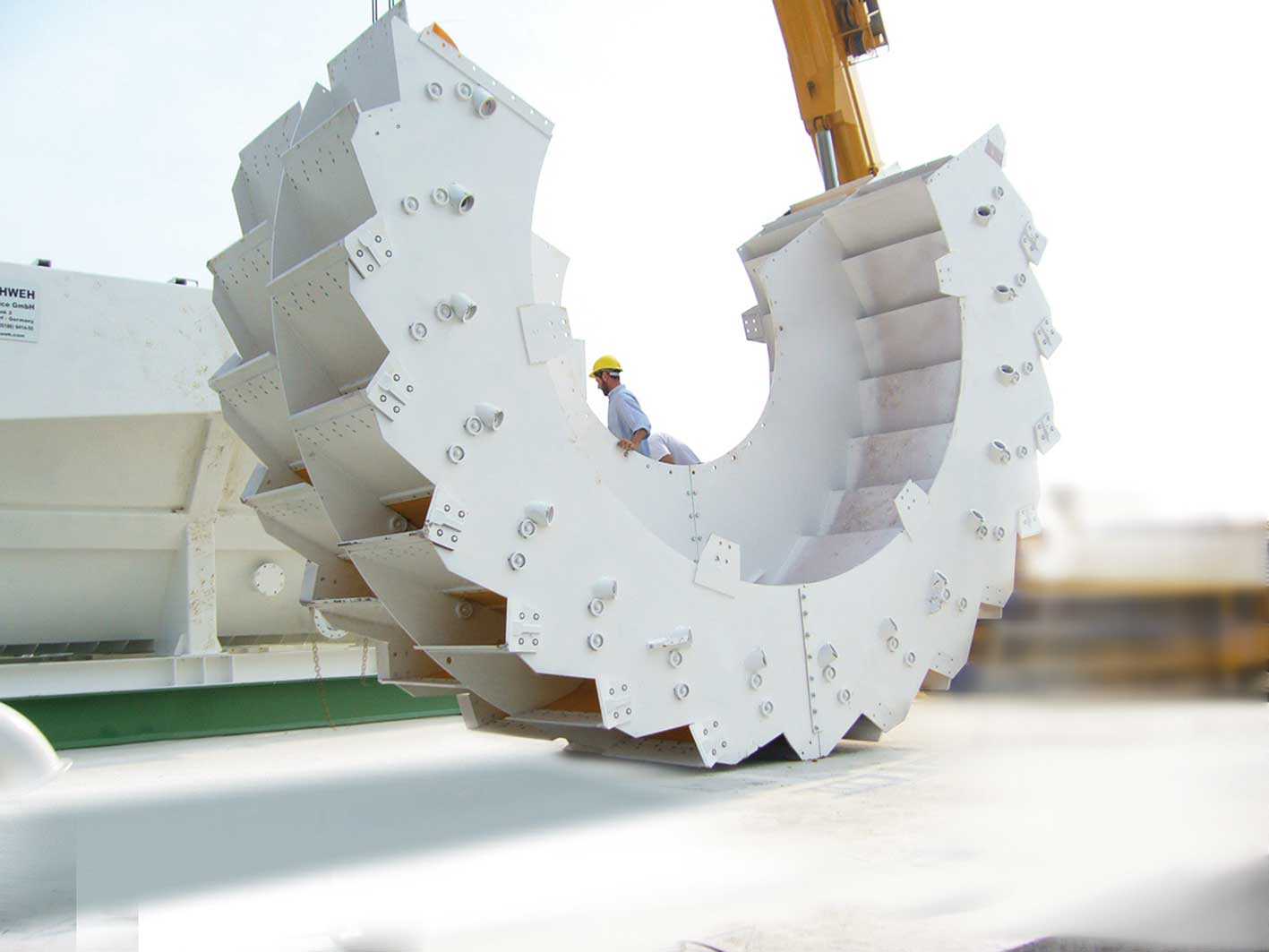

bucket wheels

Refining raw sand and gravel

The world's largest bucket wheel programme

Washing and classifying are therefore among the most important phases in their preparation. Coarse-grained material is already cleaned of impurities during screening. Special washing, dewatering and recovery systems are required for fine-grained material such as sand or grain mixtures. The STICHWEH washing and dewatering bucket wheel is used especially for this purpose.

Classify perfectly

Our bucket wheel series are perfectly tailored to your project requirements and the most diverse operating conditions. Due to the different requirements and geological material conditions, we have specific bucket wheel solutions for different applications. Why can we do this? Because we are the inventors of the washing and dewatering bucket wheel.

Designed to fit perfectly

The feed mixture of sand, gravel and water is fed to the bucket wheel by a suction dredger, pneumatic dredger, floating grab or preparation plants. The solids are bearing in the bucket wheel trough and are discharged by the bucket wheel. The scoop wheel buckets are fitted with special plastic screens with different gap widths. The extended suction chambers create a natural vacuum that minimises dewatering. A large number of adjustable overflow weirs are arranged in the trough. This makes it possible to extract fine sands or to remove unwanted fine sands.

Bucket wheel rows

Five different series are available for the different geological material conditions and requirements: from simple gravel dewatering to cleaning offine sand, classification of fine sand and fine sand recovery.

Our current bucket wheel programme

E series

- Within the treatment process and mainly for direct feeding by suction excavators with a mixture capacity of up to 5,000 m³/h and a solids volume of up to 1,000 m³/h. e.g. bucket wheel 2 x E 6518 H wheel diameter 6,500 mm, wheel width 2 x 900 mm, capacity 500 m³/h each.

ES ... BB series

- Sand recovery within a preparation plant, if optimum fine sand recovery is also required. e.g. bucket wheel ES 5014 BB wheel diameter 5,000 mm, wheel width 2 x 700 mm, capacity 250 t/h sand.

ES ... BL series

- Sand recovery, if any loss of fine sand is to be avoided.

- They have the same trough width as the fine sand scoop wheels and differ only in the larger bucket volume and the more powerful drive.

- e.g. bucket wheel ES 5014 BL 100 Wheel diameter 5,000 mm, wheel width 1,400 mm, trough dimensions 5,200 x 10,000 mm.

FS ... BL series

- For fine sand recovery. They are characterised by a large calming surface and low speed.

- e.g. bucket wheel FS 2707 BL 58 Wheel diameter 2,700 mm, wheel width 700 mm, trough dimensions 2,800 x 5,800 mm.

DSD ... BL and 3S ... BL series

- For intensive washing, grading and dewatering of heavily soiled sand:

- With computer-controlled sand dosing for the production of 2 or 3 different sand fractions.

- e.g. bucket wheel DS 2709/07 BL 100 with double drive.

Wir haben’s gemacht

Media / Downloads

- Product film

- Product documentation

- Press articles