Task

The customer was looking for a high performance and efficient solution for separating light materials (e.g. coal, shale, iron oxide, pumice, shells, ...) that are harmful to properties of concrete with the goal of extracting valuable raw materials for further processing or direct use, e.g., in the building industry.

Requirement

Integrating the machine on site and into the workflows had to be as simple, economical and ecologically efficient as possible. To meet the increasing requirements with regard to technical and economically efficient classification the chosen sorting method had to have a grain size range as large as possible, high performance capacity as well as maximum operating safety.

Successful in use

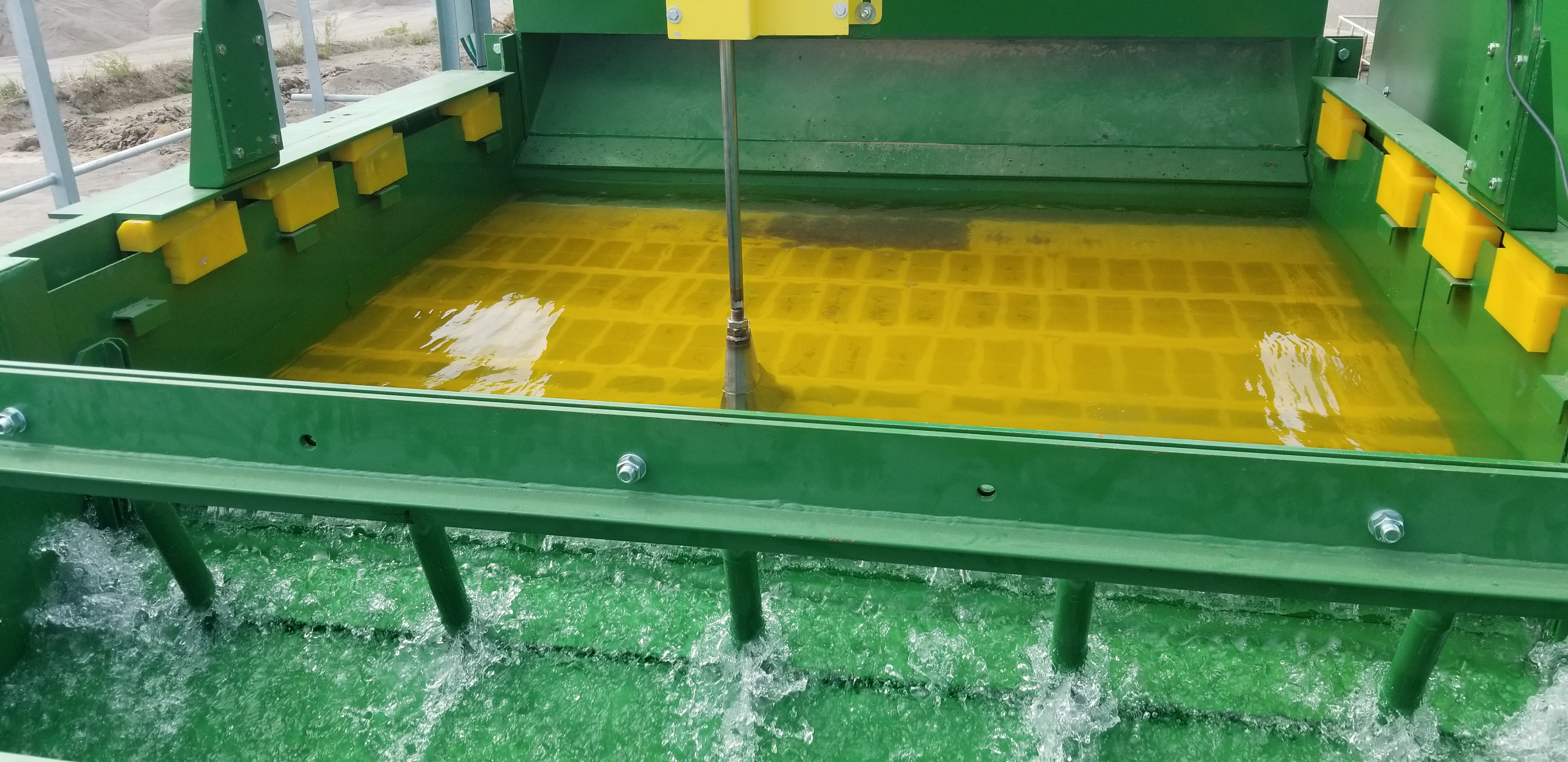

The customer selected the STICHWEH Jig 2500 SG. The high performance jig has been in operation in Denmark, since 2018, separating out material that is harmful to properties of concrete and preparing raw materials in large quantities and with high quality for further processing or direct use in concrete construction.

- Output 170 t/h

- Grain size 2 – 32 mm

- Air requirement 2500 m3/h

- Air pressure 0.4 bar

- Water requirement 410 m3/h

- Water pressure 1 bar

The discharged light materials are drained through a dewatering mesh screen and conveyed to a tip.